Built-in Carpentry and Cabinet Removal for Residential Property at Bidadari

Services Provided

Project Overview

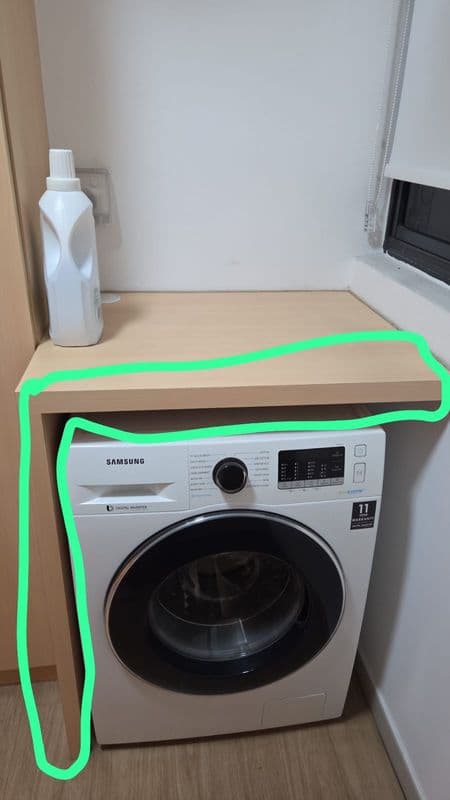

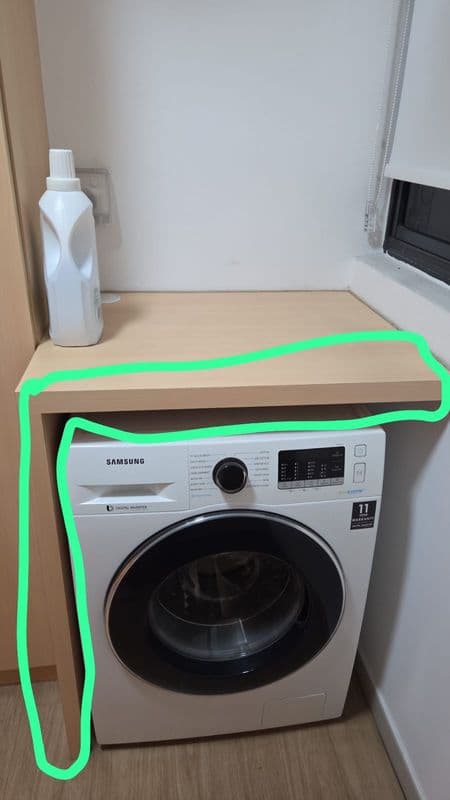

This residential project involved the dismantling and removal of built-in carpentry and cabinets within a utility space, emphasizing precision and care to support a seamless renovation process. As experts in residential demolition, we were tasked with performing meticulous dismantling services while ensuring minimal disruption to the property and its surroundings. The project was focused on the careful removal of kitchen and cabinet fixtures, maintaining the integrity of the remaining elements, and preparing the space for the next phase of renovation.

Our approach was guided by a commitment to delivering professional workmanship and prioritizing dust control, safety, and protection of non-demolition areas. The well-maintained condition of the key fixtures, such as the washing machine and surrounding structures, highlights our dedication to precision and care during the execution of this project.

Technical Challenges

Working Around Existing Fixtures

The presence of non-removable fixtures, such as the washing machine, introduced a challenge in ensuring that these elements remained undamaged throughout the dismantling process. Our team needed to execute the removal of built-in carpentry and cabinets with exacting precision to avoid scratches, dents, or debris accumulation on these critical fixtures.Dust Control in a Confined Space

Utility and laundry areas are often compact, presenting challenges in managing dust and debris during demolition. Proper containment measures were essential to prevent dust from dispersing into surrounding areas, especially since the property is residential and likely occupied. Achieving this required the use of protective coverings and regular cleanup during the dismantling process.Minimizing Structural Impact

The delicate task of removing built-in cabinets and carpentry without impacting the structural integrity of adjacent walls and surfaces required careful planning and execution. Given the visible remnants of tile removal and ongoing demolition, our team had to remain vigilant in ensuring that nearby surfaces remained intact and undamaged.Handling Limited Ventilation

Utility spaces often have limited ventilation, which necessitated extra attention to air quality and safe working conditions. While protective screens were employed to contain dust, our team also maintained proper ventilation throughout the process to ensure a safe and efficient working environment.

Project Considerations

Key considerations for this project included the safety of the surrounding environment, the protection of non-demolition areas, and the need for clear communication with the homeowner.

Safety Measures

We prioritized safety by protecting all non-demolition areas with coverings, as seen in the window screening and the intact condition of surrounding fixtures. This ensured that dust and debris were contained, reducing the risk of contamination or damage to areas not involved in the demolition.Protection of Surrounding Areas

Particular care was taken to preserve the condition of the washing machine and its platform, as well as adjacent walls and windows. The clean state of the surrounding areas reflects the effectiveness of our dust control measures and the precision of our dismantling work.Client-Centered Approach

Throughout the project, we maintained clear communication with the homeowner, providing updates on progress and ensuring alignment with their expectations. This client-centered approach reflects our commitment to delivering not only high-quality results but also peace of mind during the renovation process.

Results

The completed demolition work exemplifies our dedication to professionalism and quality. The utility area was left clean, uncluttered, and prepped for the next stage of renovation. All built-in cabinets and fixtures were dismantled and removed with precision, leaving the surrounding elements, such as the washing machine and wooden platform, unharmed and intact.

The effectiveness of our dust control measures is evident in the spotless condition of the room post-demolition. By carefully protecting non-demolition areas and maintaining a high standard of workmanship, we ensured that the space was ready for immediate use or further enhancement without additional cleaning or repairs.

This project showcases our expertise in residential demolition and our ability to handle technical challenges with care and precision. The homeowner was highly satisfied with the results, particularly the attention to detail and the orderly execution of the work. At HackingSG, we take pride in delivering tailored solutions that meet the unique requirements of each residential property, ensuring a smooth and stress-free renovation experience for our clients.

Project Gallery